Pipeline

branches

To add a new branch, select a pipeline

(or any already existing branch) in the project tree and click the  button of the Components

toolbar (or use the corresponding Insert

menu item) - the new branch will be added to the project tree after the

selected element. It is important to remember that the order of branches

in the project tree is not essential for calculating the pipeline. Therefore,

branches can be added to the pipeline in any order; if they were inserted

in the wrong order, they can be swapped at any time using the standard

Cut/Paste commands of the Edit toolbar, the Edit

menu, or the context menu (called by right-clicking on a branch in the

project tree) - for more information, see here.

button of the Components

toolbar (or use the corresponding Insert

menu item) - the new branch will be added to the project tree after the

selected element. It is important to remember that the order of branches

in the project tree is not essential for calculating the pipeline. Therefore,

branches can be added to the pipeline in any order; if they were inserted

in the wrong order, they can be swapped at any time using the standard

Cut/Paste commands of the Edit toolbar, the Edit

menu, or the context menu (called by right-clicking on a branch in the

project tree) - for more information, see here.

In

addition, a branch can be added by activating one of the pipeline nodes

in the diagram - in this case, this node will be considered the default

starting node of this branch.

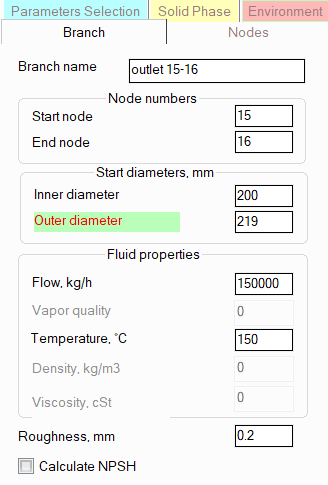

After

adding a branch, a list of its initial data will be displayed in the Object

Properties Window:

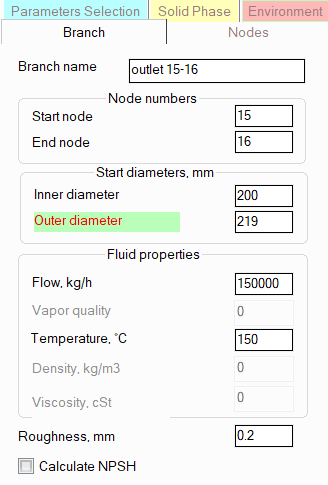

branch name - specify the

name for each branch that you would like to see in the reports with

the calculation results for this pipeline;

start and

end node numbers - please note that only integer values

(letters and other symbols are not allowed) with no more than 8 characters

can be used as node numbers (the program does not currently support

9-digit or more node numbers) and it is necessary to ensure that node

numbers are unique -

so that the same node number is not used for two or more different

points in the pipeline. The start and end node numbers determine the

direction of the branch, however, the flow direction in this branch

may be the opposite - see below for more information. To quickly change

the direction of a branch, use the "Reverse direction" command

in the context menu called by right-clicking on the branch in the

project tree or the similar button in the Edit

toolbar, or use the corresponding item in the Edit

menu;

start diameters -

here you need to specify the "initial" diameters, i. e.

the diameters of components at the beginning of a given branch before

its first change (for example, at a reducer or other element with

a change in diameters). If there are no elements with a change in

diameter in a branch, then all elements of the branch will have diameters

equal to the "initial" ones. Depending on the type of calculation,

diameters can be specified in the initial data or be unspecified:

When

performing diameters calculation

of a pipeline, the diameters are unknown, so they are usually

not specified in the initial data (they are left equal to zero).

However, for some branches, the diameters may be known - for example,

if part of the calculated pipeline model has already been designed

(or even built) and it is necessary to determine the diameters

only for the rest of the pipeline system. In this case, the known

diameters of the branches are specified in the initial data, and

for branches with unknown diameters, they are left unspecified.

In branches with unspecified diameters, reducers and other piping

components with a change in diameter are not allowed.

When

performing an

isothermal flow analysis, it is sufficient

to specify only the value of the inner diameter; diameters must

be specified in all branches.

When performing heat analysis and waterhammer calculations,

both the inner and outer diameters must be specified for each

branch of the pipeline.

Please note that when changing the

specified branch diameters, the

program will not only automatically adjust the values of the diameters

of the components of this branch (up to the first element with a change

in diameter if any), but will also change the values of the

radii of the bends and elbows in this branch if they are equal to the

standard value of 1.5*DN (for pipes with DN < 500mm) or 1*DN (for

pipes with DN >= 500mm).

fluid flow

rate - depending on the hydraulic calculation task being

solved, the flow rate value can be either known - in this case it

is specified, or an unknown sought value - in this case it is not

specified (for more details, see boundary conditions of hydraulic

calculation). For branches with unknown flow rates, it

is allowed to specify approximate flow rate values as an "initial

approximation" in the calculation, however, the entered values

must not 'conflict' with the flow rate values in neighboring branches

(therefore, if there are doubts about the flow rate values in such

branches, it is better not to specify them at all than to specify

incorrect values). Please note that the flow direction in a branch

may not coincide with the direction of the branch itself. For example,

if the branch has an initial node 1, the end node 2 (that is, the

branch is directed from the 1st node to the 2nd), and the flow must

be directed vice versa, from node 2 to node 1, it is necessary to

specify a negative value of a flow rate for the branch. Similarly,

if in the calculation results for any branch/branches the fluid flow

rate appeared to be negative, this means that the flow in this branch

goes in the direction opposite to the direction of the branch.

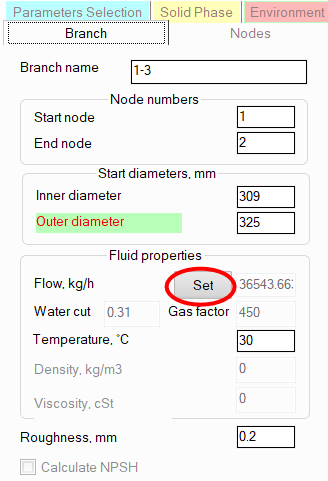

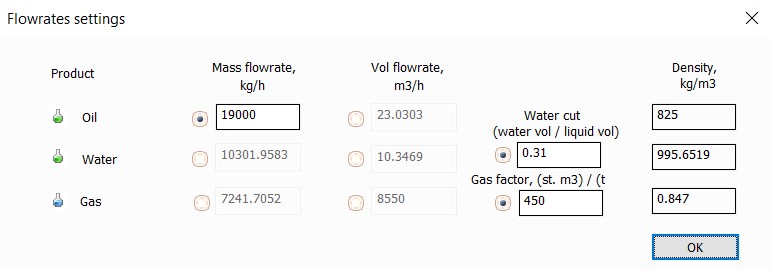

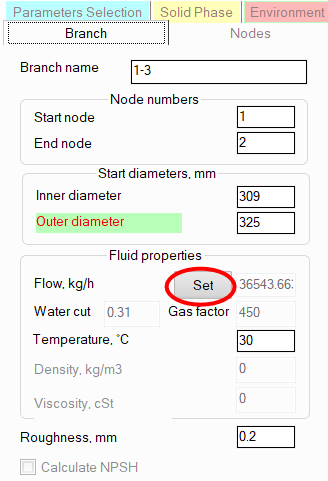

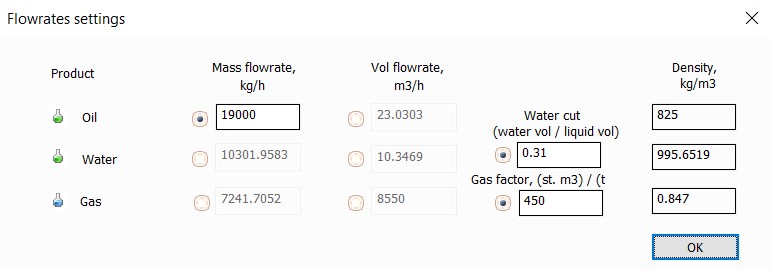

A

special case is the assignment of flow rates for "three-phase"

mixtures (of oil, water and natural gas). If three fluids are specified

in the project tree, then the flow rates of each of the three phases (oil,

water and gas) must be specified separately by clicking the corresponding

button opposite the flow rate in the Object Properties Window for the

branch:

The

flow rates can be specified either explicitly (in kg/hour, m3/hour and

other units) for each of the phases, or in the form of oil flow rate (it

is mandatory) and water cut and gas factor coefficients (or any combinations

of these values with each other):

vapor quality (a.k.a. mass gas content) -

this parameter is the mass flowrate fraction of gas in the gas-liquid

flow, and is used only when calculating gas-liquid flows. Its value

can lie in the range from 0 to 1. When the gas content = 0, the flow

consists entirely of liquid (the gas fraction is 0); when the gas

content = 1, the flow consists entirely of gas; when the vapor quality

values between 0 and 1, the flow is in the vapor-liquid state. The

vapor quality should be specified for all source branches (the initial

nodes of which are source nodes for the pipeline system). For other

pipeline branches, the gas content can be omitted; it will be determined

by calculating the previous (in the direction of flow) pipeline branches.

Depending on the selected model

for calculating two-phase flows, the value of this

parameter will be interpreted in the calculation differently:

when

calculating a flow taking

into account flashing/condensation of the fluid

(when the "Undefined" phase state of the fluid is specified),

the entered value of the vapor quality is interpreted as the fraction

of gas at

the initial point of the flow. And its further change along

the pipeline, caused by boiling/condensation of the fluid, is

determined during the calculation. In addition, when specifying

the "Undefined" fluid phase state, it is allowed not

to specify the value of the vapor quality if the pressure and

temperature of the flow are specified for this initial point of

the pipeline. In this case, the gas content will be determined

in the phase equilibrium calculation for the specified pressure

and temperature. However, it is important to remember that for a single-component fluid, only

a single-phase state (liquid or gas) can be modeled in this way,

since boiling/condensation of a single-component fluid occurs

at a constant temperature if the pressure is fixed, and vice versa

- if the temperature is fixed, then at a constant pressure. That

is, any gas fraction from 0 to 1 can correspond to each pair of

pressure and temperature values. Therefore, if a single-component

fluid is in a vapor-liquid state at the starting point of the

pipeline, its vapor quality (gas content) must be specified.

when

calculating a "frozen"

two-phase flow (when two fluids are specified in the project tree,

describing the parameters of the liquid and gas phases separately),

the entered value of the gas content is considered constant throughout the entire

branch. In subsequent branches, the gas content may change

(for example, when mixing two flows with different gas contents),

which is calculated by the program automatically. Since in the

case of a "frozen" flow, the effects of boiling/condensation

of the fluid along the pipeline are not taken into account and

the phase equilibrium is not calculated, the gas content must

be specified in all source branches (it is impossible to determine

it by pressure and temperature as in the case of a flow with boiling/condensation

described above).

If

you are unsure of what type of calculation you will be performing for

a pipeline, just in case, set the temperatures in all branches.

Please

note that when calculating two-phase flows using the model taking into

account boiling/condensation of the fluid along the pipeline (when the

"Undefined" fluid phase state is specified), it is permissible

not to specify the temperature in the source branch if the vapor quality

value for this branch is specified greater than 0 but less than 1. In

this case, the flow temperature will be automatically determined by calculating

the phase equilibrium for the specified gas content and pressure at the

starting point. If both the temperature and the gas content (greater than

0 but less than 1) are specified for the branch, then it is considered

that the gas content value has a higher priority, so the flow temperature

in this case will be recalculated when calculating the phase equilibrium

for the specified pressure and gas content.

A special case is pipelines with

an "Undefined" fluid phase state, consisting of one branch,

in which the pressure at the end node is specified. For such pipelines,

the specified values of the mass gas content and/or temperature in the

branch are interpreted as the gas content/temperature of the flow at the end point of the pipeline,

and an "inverse" heat and hydraulic calculation is performed

for them in order to determine the required pressure, temperature and

gas content of the flow at the inlet of the pipeline. Such a hydraulic

analysis calculation task is, in particular, quite often used in the calculation

of "transfer" pipelines feeding oil in a vapor-liquid state

from furnaces/heaters to a distillation column.

density

and viscosity of the fluid

- are set only in the case when manual input of properties is

used for the liquid product, but the table of fluid properties vs.

temperature is not specified. In this case, the fluid properties (density

and viscosity) are set separately for each pipeline branch;

roughness

of the inner surface of the pipe - initially this parameter

is set for the

pipeline, therefore by default the same roughness value

will be set for the branch and used in the calculation as in the pipeline

to which this branch belongs. However, if necessary, different roughness

values can be set for different branches of the pipeline (for example,

if part of the pipeline is "old", part is "new"

or if the pipeline is partially made of steel pipes, partially of

plastic pipes, etc.).

calculate NPSH -

by default, the calculation of NPSH in the pipeline is not performed

(since it's usually not of a great interest for the major part of

any piping system), therefore the user must "mark" those

branches for which it is necessary to calculate the NPSH by enabling

this option for these branches.

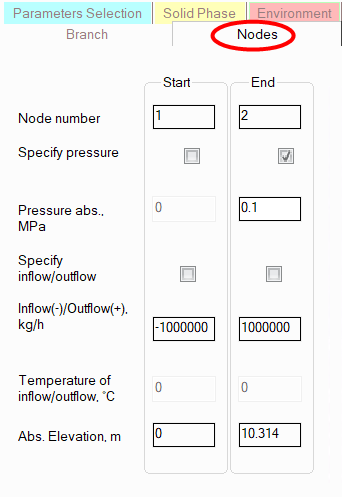

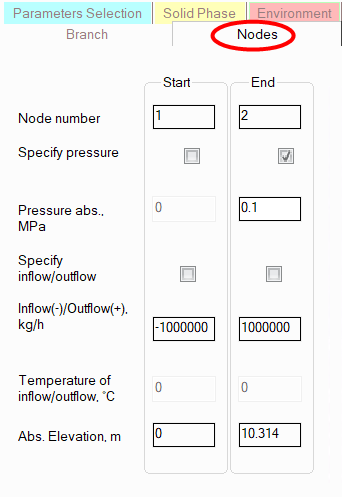

Setting

branch nodes parameters

The

branch node data is specified in the Nodes tab of the Branch Properties

Window; these include:

pressure

in nodes - depending on the hydraulic calculation task

being solved, the pressure value in a node can be either known - in

this case it is specified, or an unknown sought value - in this case

it is not specified (for more details, see boundary conditions of hydraulic

calculation). Please note that pressures in intermediate

pipeline nodes are usually not specified. Incorrect specifying of

pressure in an intermediate node can lead to an incorrect calculation

task formalization, since the entered pressure value will be considered

a boundary condition for hydraulic calculation. This can lead to a

recalculation of fluid flow rates in the branches associated with

this node.

inflow/outflow

in a node - instead of assigning the flow rate on the

"Branch" tab, you can assign the fluid inflow/outflow values

in the branch nodes. If the node is terminal (i.e., the initial or

final node of the pipeline system), then entering the inflow/outflow

in this node is equivalent to entering the flow rate in the branch

starting/ending in this node (you can assign either the flow rate

in the branch or the inflow/outflow in the node - whichever is more

convenient to you). Please note, that in this case for an inlet

node the inflow

(negative value) should be specified, while for an outlet

- the outflow (positive

value). If the node is intermediate, then assigning the inflow/outflow

in such a node can be used to simulate the removal of a portion of

the fluid from the pipeline (i.e., the outflow - with the "+"

sign) or, conversely, its supply to the pipeline "from the outside"

(the inflow - with the "-" sign). Similar to the fluid flow

rate in a branch, the inflow/outflow values in nodes, depending on

the hydraulic calculation task being solved, can be either known -

in this case they are specified, or unknown - in this case they are

left unspecified (for more information, see the boundary conditions of hydraulic

calculation). If the "Specify inflow/outflow"

checkbox is not checked, then for this node, the Inflow/Outflow field

will display the inflow/outflow value calculated based on the balance

of fluid flow rates specified in the branches related to this node.

Please note that:

non-zero

inflows/outflows are not allowed for nodes with tees;

it

is not allowed to specify inflows/outflows in nodes when calculating

multiphase flows - in this case, fluid flow rates should be specified

by branches.

temperature of inflow/outflow -

when specifying the inflow of the fluid in the node, its temperature

must also be specified. This temperature may differ from the temperature

of the flow entering this node from other branches, which will be

taken into account in the heat calculation of the pipeline;

absolute

elevations of nodes - these fields display the absolute

heights of nodes automatically calculated by the program. The calculation

is performed as follows: the starting point of the first pipeline

branch is taken as a certain "zero mark" (with an absolute

elevation of 0 m) and then, based on the entered data on the geometry

(elevation differences) of the elements of this branch, the elevation

mark of the end node of the branch is calculated, and similarly, the

elevation marks of all other nodes of the pipeline are calculated

for further branches. If necessary, you can specify your own zero

mark, or make any other height of any node of the pipeline the starting

point. To do this, select the corresponding node of the pipeline (for

more details, see here)

and set the desired absolute elevation value for it - the heights

of the other nodes will be recalculated relative to the entered value

automatically.

Please note

that node parameters can also be set by directly selecting the required

node of the pipeline - for more details, see Working with pipeline nodes.

button of the Components

toolbar (or use the corresponding Insert

menu item) - the new branch will be added to the project tree after the

selected element. It is important to remember that the order of branches

in the project tree is not essential for calculating the pipeline. Therefore,

branches can be added to the pipeline in any order; if they were inserted

in the wrong order, they can be swapped at any time using the standard

Cut/Paste commands of the Edit toolbar, the Edit

menu, or the context menu (called by right-clicking on a branch in the

project tree) - for more information, see here.

button of the Components

toolbar (or use the corresponding Insert

menu item) - the new branch will be added to the project tree after the

selected element. It is important to remember that the order of branches

in the project tree is not essential for calculating the pipeline. Therefore,

branches can be added to the pipeline in any order; if they were inserted

in the wrong order, they can be swapped at any time using the standard

Cut/Paste commands of the Edit toolbar, the Edit

menu, or the context menu (called by right-clicking on a branch in the

project tree) - for more information, see here.