Reservoir

To add

a new reservoir, click the button  of Components toolbar

and select the equipment type "Reservoir"

(or

use the corresponding item of "Insert

- Component - Equipment"

menu). Please note that

the new component is added to the project tree after the currently selected

element. Therefore, to add a new component after an existing one, select

it in the project tree or in the graphic window and add the new component.

If you need to add a new component to the beginning of a branch, select

the branch in the project tree and add the new component.

of Components toolbar

and select the equipment type "Reservoir"

(or

use the corresponding item of "Insert

- Component - Equipment"

menu). Please note that

the new component is added to the project tree after the currently selected

element. Therefore, to add a new component after an existing one, select

it in the project tree or in the graphic window and add the new component.

If you need to add a new component to the beginning of a branch, select

the branch in the project tree and add the new component.

The reservoir element is

used to model the hydrostatic head of the fluid contained in the reservoir

(or any other vessel/device) and to account for pressure losses at the

fluid abrupt acceleration/deceleration at entering the pipeline from reservoir

(or exiting from pipeline to reservoir). Reservoirs may

only be installed as the first or last element of the pipeline.

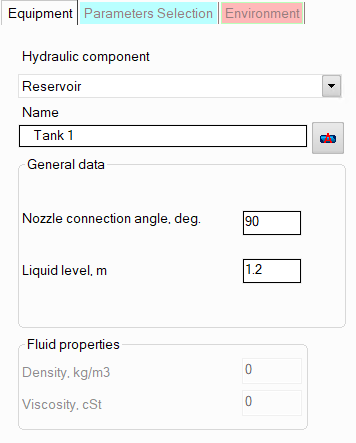

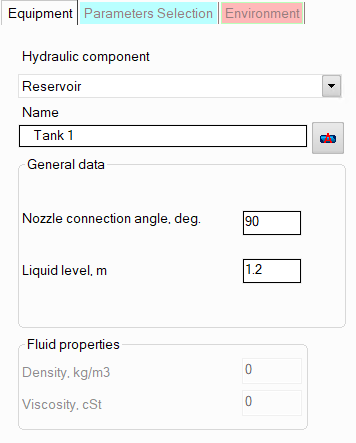

After adding a reservoir,

its characteristics will be displayed in the Object Properties Window:

name -

by default, the name of any piping component coincides with its type,

but if necessary, the name can be changed in this field. When changing

the hydraulic component type (when selecting different types of equipment),

its name will also change, but only if it has not been previously

changed to another manually. Specify the name that you would like

to see for this element in reports with calculation results. To display

the name of a pipeline element on the diagram, click the corresponding

button to the right of its name;

nozzle

connection angle to the shell/bottom of the reservoir

- the default angle is 90° as

the most common case; if necessary, it can be replaced with another

one (depending on this angle, the hydraulic local resistance

of the nozzle edge may be slightly different);

liquid level -

the liquid level in a reservoir is the vertical distance between the

surface of the liquid in the reservoir and the center of the cross-section

of the nozzle to which the pipeline is connected. In the calculation,

the liquid level in the reservoir is considered constant, therefore,

to calculate systems with a variable liquid level in the tank, several

calculations can be performed sequentially, setting different values

of the liquid level.

Please note that the pressure at

the node with reservoir (which is usually a known value in hydraulic calculations)

should be specified equal the pressure "at the top" of the reservoir

(above the liquid level). If you specify the pressure at the inlet of

the flow into the pipeline as the pressure at the node, then you should

not enter the reservoir element in this case, since the liquid level is

already taken into account in the specified pressure value.

If it is necessary to model a "flow-through"

tank (or other similar apparatus),

then first of all it is necessary to understand whether a flow break occurs

in this equipment/tank:

if it occurs (i.e., the flow stream enters

the apparatus above the

liquid level in it), then the piping model in this place should

be "broken" - the points of flow entry into the equipment

and flow exit from it should be modeled as different pipeline

nodes (with different numbers), the same pressure values should

be specified for these nodes (equal to the pressure in the free

zone of the apparatus), the pipe

exit component should be added before the flow

entry node into the apparatus, and a reservoir with the corresponding

liquid level should be modeled right after the node of flow exit

from the apparatus into the pipeline;

if

there is no flow break in the apparatus (i.e., the flow enters

the apparatus below the

liquid level), then this apparatus should be modeled not as a

reservoir, but as a sequence of a pipe exit (simulating

the exit of the flow from the pipe into the apparatus), an elevation

change (simulating the "column

of liquid" between the center of the inlet and outlet pipes

of the apparatus) and a pipe entrance (simulating

the entry of the flow from the apparatus into the pipeline after

it).

of Components toolbar

and select the equipment type "Reservoir"

(or

use the corresponding item of "Insert

- Component - Equipment"

menu). Please note that

the new component is added to the project tree after the currently selected

element. Therefore, to add a new component after an existing one, select

it in the project tree or in the graphic window and add the new component.

If you need to add a new component to the beginning of a branch, select

the branch in the project tree and add the new component.

of Components toolbar

and select the equipment type "Reservoir"

(or

use the corresponding item of "Insert

- Component - Equipment"

menu). Please note that

the new component is added to the project tree after the currently selected

element. Therefore, to add a new component after an existing one, select

it in the project tree or in the graphic window and add the new component.

If you need to add a new component to the beginning of a branch, select

the branch in the project tree and add the new component.