|

PASS/NOZZLE-FEM 3.5. Program Manual |  |

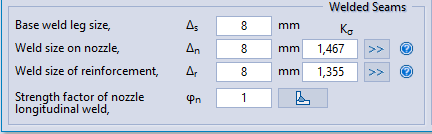

In the «Weld seams» data group need set the weld size along the base shell surface and along the attachment, strength factors (fig. 3.22), weld seam type, seam treatment are specified. The longitudinal strength factor for base shell and nozzle is used for strength assessment as per GOST 34233 for finite elements that are not included in junction areas.

To calculate the fatigue strength in the elastic assessment, it is necessary to set the fatigue strength reduction factor Kf.

When calculating according to ASME VIII.2, it can be taken from tables 5.11 and 5.12 [4]. The factor value is set immediately after the corresponding weld size (fig.3.23). This is also valid for other codes, except for GOST 34233.

|

| Fig. 3.23. Setting $K_f$ |

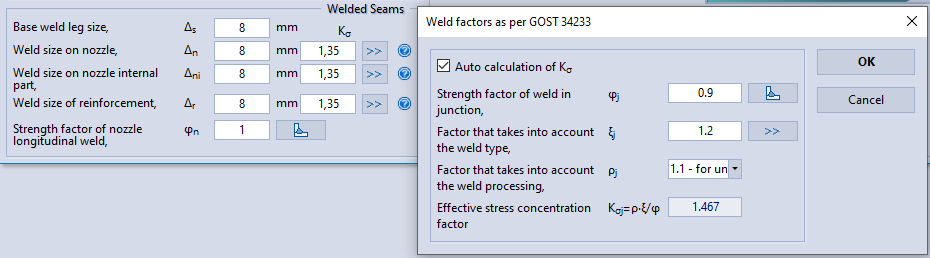

When calculated in accordance with GOST 34233.6-2017, it is called the effective stress concentration factor (fig. 3.24) and it can be determined by the formula 11 [15]:

$$ K_{\sigma} = \frac{\rho\xi}{\varphi}, $$where factor ξ are defined as per tab. 1 [15]; factor ρ equal to 1.0 for polished weld surfaces, and 1.1 for unpolished weld surfaces; φ - weld strength factor that is defined as per GOST 34233.1 (see next section).

When calculating according to GOST 34233.6-2017, it is necessary to set all three factors in the dialog box (fig. 3.24), the factor Kσ can be set manually or determined automatically using the specified formula.

|

| Fig. 3.24. Setting $K_{\sigma}$ |

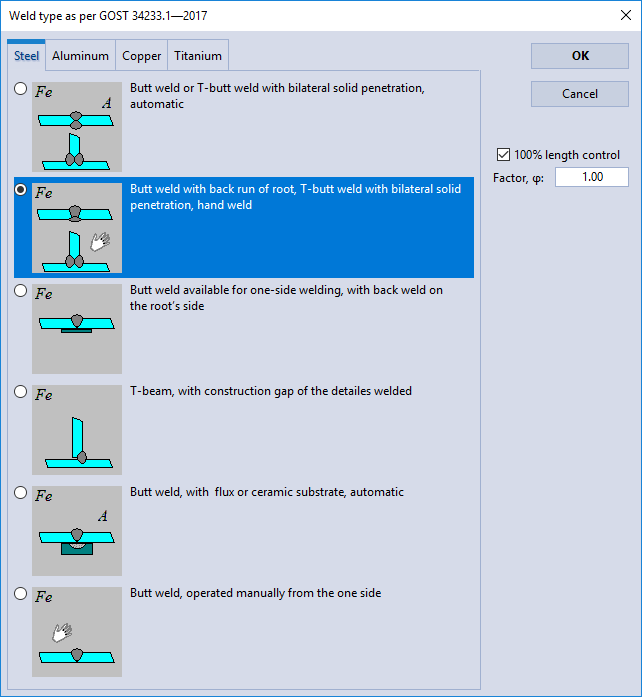

Weld strength ratio (fig. 3.25) is used in stress analysis

for base shell, nozzle, support and junction area and is set depending on its type as per

[12] by  button.

button.

|

| Fig. 3.25. Dialog of weld strength ratio |

PASS/NOZZLE-FEM 3.5. Program Manual

Copyright © 2017-2026, PASS Team