(m)

Calculation liquids containing solid phase (a.k.a. settling slurry flow)

The calculation of the liquid flow containing a solid phase (a.k.a. “slurry” flow) is carried out according to the DHLLDV mechanistic model, described in detail in [1]. The following parameters should be set as the initial data on each of the branches:

Solid particles fractional composition (particle diameter differential distribution)

Solids density

Volume fraction of solid phase

The user can enter either the spatial or the transport (delivered) volume fraction of the solid phase. The transport volumetric fraction refers to the ratio of the volumetric flow of solid particles to the total volumetric flow rate of the mixture. Spatial volume fraction refers to the ratio of the cross-sectional area of the pipe occupied by solid particles to the total cross-sectional area of the pipe.

Slurry flow calculation can be performed for solids with diameters up to 45 mm, density from 1140 to 3650 kg/m3 and solid content up to 45% by volume [1].

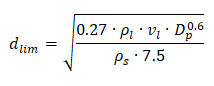

Please note that the slurry calculation may be inaccurate if the liquid contains fractions of solid particles with a diameter less than calculated by the formula below [1]:

|

(m) |

where

and

and  – density of solid and liquid phase, respectively (kg/m3),

– density of solid and liquid phase, respectively (kg/m3),

– liquid velocity

(m/s),

– liquid velocity

(m/s),

–

pipe diameter (m).

–

pipe diameter (m).

The particles with diameters below this value practically don't settle in the liquid, which is currently not taken into account in the program methods.

If there are pumps in the piping model, their head curves are automatically recalculated based on the solid phase parameters according to the method [2]. For homogeneous mixtures of liquid with solid particles, their effective viscosity in this case is calculated using the Thomas formula [1].

References

1. Miedema SA (2017). Slurry Transport. Fundamentals, A Historical Overview & The Delft Head Loss & Limit Deposit Velocity Framework, 2nd edition

2. American National Standard for Rotodynamic (Centrifugal) Slurry Pumps for Nomenclature, Definitions, Applications and Operation. ANSI/HI 12.1-12.6-2011. American National Standards Institute, Inc